Plaster Details

Details are Crucial

HempStone has been consulting on plaster details for the Goshen, MA hempcrete house and conferring with Alex Sparrow of UK Hempcrete on window and door details especially. The United Kingdom benefits from a robust culture of traditional plasterers, and they have a defined and clear set of supporting accessories to go with it.

After conducting primary research of tapes on hempcrete and lime plaster, we've ruled out all of the tapes we've tested as a robust detail for airtightness and vapor transportation in these critical junctures (read our article on High Performance Test Results on Hempcrete and Lime Plaster to learn more). Instead, we are looking to beads - either in PVC, zinc, or stainless steel to provide the critical junctions needed.

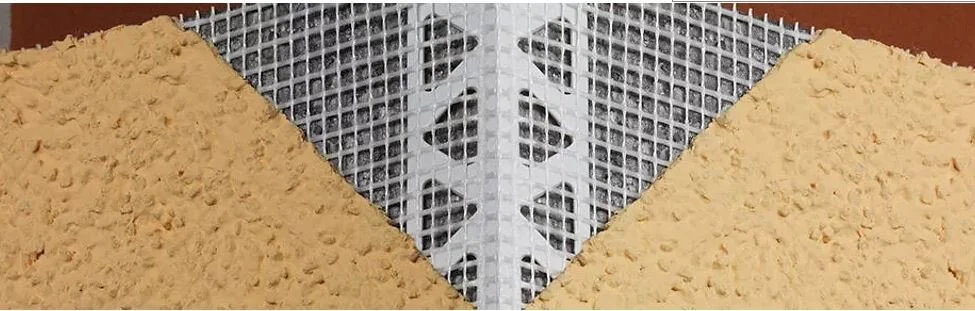

For this project, we chose PVC fiber mesh corner and lintel beads over a metal version because the folks plastering the house are learning on the job, and the mesh wing provides a solid and extended key for the plaster. It's more robust and forgiving than the beads that don't have them. Once these installers become experienced plasterers, I’ll switch our recommendation to zinc or stainless beads due to the toxicity of PVC. Whatever you do, don't go for galvanized metal. Galvanized metal left partially exposed - as with casing beads at windows and door junctions or drip edges - will rust over time and stain your plaster.

While PVC is inert once a structure, the manufacturing of PVC is toxic, and creates an inequitable working environment for those who work in and live near the manufacturing plants. Unfortunately, this toxicity is not reflected in the cost, and in fact, PVC items are always less expensive than their metal counterparts. Zinc comes in about 4 times the cost of PVC, and stainless steel is not fabricated at significant scale due to cost. However, if your local welding and fabrication shop offers stainless steel work, this is a good way to engage your dollars locally. You can simply provide a profile (drawing or material sample) and let your local functional artisan set to work.

Drip beads and Casing beads are altogether different than UK versions. Our stucco industry in the US does not offer drip beads that are familiar to our European counterparts. Instead of obtuse, downward angled beads which shed water, US beads are cut 90 degrees. While there are angled beads with weep holes for the stucco industry, the bead profiles do not have penetrations that allow for the plaster to “key” or connect to the substrate behind the bead, as the images below suggest. This key is essential to retain a continuous, airtight connection.

While there is a stucco industry, there is not a plaster industry to speak of, so MOST beads in the US are stucco-based. This translates for the most part, but some key profiles have been tricky to source within the US. Most especially tricky to find are the alkaki-resistant mesh wing and the drip profile. We have found one US-based company who offers these items, and we'll test their performance in the Goshen house.

Corner beads and casing (edge) beads are of good quality here and reasonably accessible if you can work without the mesh wing. At HempStone, our focus is always on accessing materials as locally as possible. Therefore, we are working closely with bead manufacturers in both plastic and metal to provide the necessary plaster accessories for robust plaster construction. Another advantage of the US materials is that the sizing is optimized for our US system, offering 1/2" to 7/8" in 1/8" increments.

Plaster details are important to get right, and the US Industry isn’t focused on providing products specifically for natural, vapor-open assemblies. If you’re using natural clay or lime plaster and looking to build an efficient, high-performance structure using natural materials, you’ll want to make sure to get the detailing just right. Look to HempStone for support and guidance on your detailing and material decisions; we help you specify exactly what you need with confidence and ease.