Goshen Hemp House

Spring of 2020 brought us a lot of firsts; many of them are downright abysmal and concerning. Fortunately, natural building offers a bright spot in this small hilltown of Goshen, Massachusetts. Nestled on 3 acres, this single family home aspires to become an affordable, deeply carbon-beneficial prototype for Village Carpentry and Landscaping, a local construction company. This new home engages a vibrant palette of natural building materials - local hardwood timbers and cherry sills, site-sourced hardwood flooring and pine interior finish, hempcrete featuring local lime, cellulose, and wood fiberboard. Together, these materials capture and store more than 12 tons of carbon dioxide in this new healthy home!

To mark this special event, the US Hemp Building Foundation sponsored a Virtual Talk & Tour in July, 2020.

In October, 2020, the house was featured at the US Hemp Building Summit. There, we showcased the progress of the house, which is in the finishing stages and will be move-in ready by the end of this year. Check out the videos at the bottom of this page to get as close as we dare during a global pandemic!

If you just want a quick introduction, watch our Quick Tour!

Lime Plaster Skillbuilding

HempStone had the joy and privilege of introducing the Village Carpentry and landscaping crew to hydrated local lime plaster. This is Catalyst’s favorite type of lime and goes on the wall like butter.

Two local professional plasterers, Steve Harrington and James Bowles, joined for the exterior lime plaster, in order to assure that the large facades on the West and North walls could be completed in one day.

Like in-situ hempcrete installation, lime plaster is an all-hands-on-deck activity, the type that builds camaraderie and a sense of team spirit, which is so fun! To learn more, check out our blog The Joy of Lime Plaster.

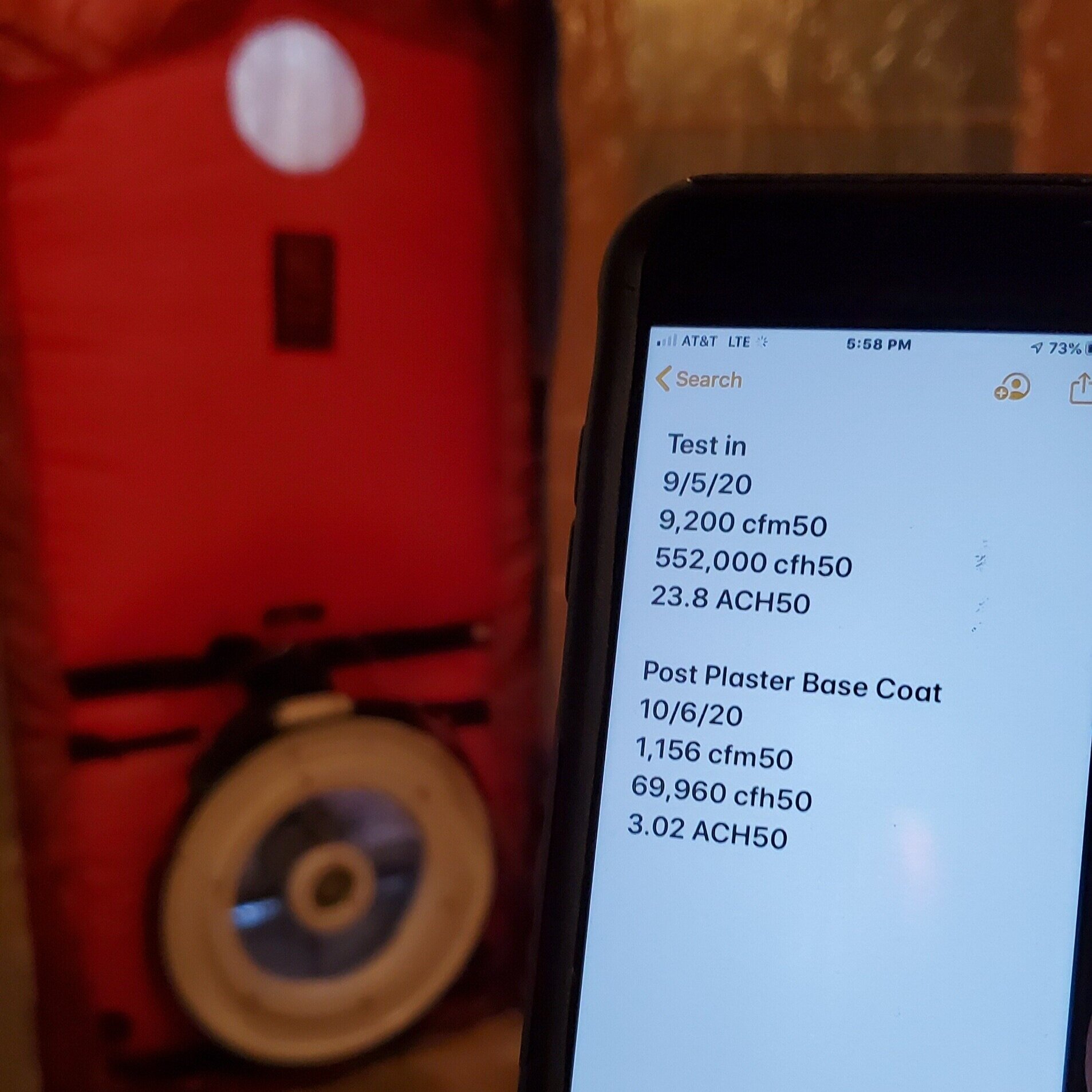

Airtightness Test Results

Hempcrete and Lime Plaster work together to create a complete assembly. Now that the first coat of lime plaster is on the exterior face of the walls, HempStone was able to test the building.

Before lime plaster was installed, the building came in at nearly 24 air changes per hour at 50 Pascal. The lime plaster reduced the airflow by 87% and met the minimum standard for new buildings.

Even without all the air sealing details buttoned up, this structure meets code standards for airtightness. Read all about our Airtightness Testing and Results!

Lime Plaster Selection

There are many types of lime, each which has an appropriate use. Some limes are more ductile, cure rates vary, and some limes are better at resisting erosion.

For this building, we had 3 factors that dictated our choice of lime: large facades with significant exposure on the windward side, a wet and harsh climate, and an impending frost date.

For these reasons, we chose to install a NHL 3.5 hydraulic lime plaster. This lime was imported from France, and will cure more quickly, be harder on the wall, and have more resistance to erosion.

Hempcrete is Complete!

Congratulations to the awesome Village Carpentry & Landscaping team for taking on a new-to-them sustainable building material, developing great efficiency systems to install hempcrete, and totally Rockin' it!

HempStone is thrilled to support and guide Village Carpentry and Landscaping in building their first hempcrete home.

Stay tuned for more details of this build, and be sure to sign up for our July 8th virtual tour!

Second Story Rising!

The 1st hempcrete home in Massachusetts has nearly finished hempcrete install! This project is exciting; combining the best of traditional and modern techniques to create a high-performing building.

Natural building methods create a very serene construction site, as shown here.

We've fallen in love with these flexible tubs, which easily allow placement of hempcrete at any wall thickness! Check out our HempStone blog post about them in our tools for the Trade series: The Humble Plastic Bucket.

Efficiency Site Solutions

The Village Carpentry team knocked it out of the park, inventing ingenious ways to maximize efficiency and utilizing tools that increased the enjoyment of the build.

Efficient work was made of putting hempcrete in the wall with the use of this skidsteer, outfitted with a concrete mixing bucket. We dig into the details in our blog post. You can read all about it our blog post For the Love of Skidsteers!

Photo Courtesy of Cory Woodard, pictured at the top, keeping tradition alive.

Hempcrete Begins

It’s official! The first Massachusetts hempcrete house is happening! Kudos to Village Carpentry and Landscaping for taking this momentous step to learn how to design and build with this new material! We’ve been thrilled to guide them along on this journey!

HempStone will be back on site every couple days to document progress and to answer crew questions as they arise - which will certainly happen as the hempcrete walls continue to rise!

Check out more details plus a photo gallery of hempcrete installation on our Hempcrete is Happening! blog post.

Timber Frame Erected

The culmination of weeks of design, framing cutting, and timber positioning occurs when the frame is erected. The traditional rite of “topping out” is completed by placing a pine bough at the topmost point of the building. For this frame, Cory did the honors, shown here at the very peak of the structure.

Learn more about Village Carpentry and Landscaping as a company and Timber Framing as a building system in our blog A Timber Frame is Raised!

Test Panel

In December of 2019, Village Carpentry and Landscaping erected this test frame panel in order to wrap their heads around hempcrete - a new construction material and methodology for the crew.

HempStone was on site to teach the techniques of hempcrete mixing, installation, and to consult on all aspects of hempcrete construction, from formwork to the creation of specialized tools to install hempcrete in hard-to-reach places.

Read more about this test wall in our Practice Makes Perfect blog post!

Local Timber

When one thinks of New England, images of bright fall colors surely come to mind. That’s because this region is quite famous for glorious deciduous forests. These hardwoods make excellent structures which last for centuries.

The craft of Timber Framing is alive and well, and has experienced a resurgence as builders and owners look closer to home for building materials. From simple cabins to elegant estates, timber framing offers a local, renewable, structurally sound solution for your building needs.

When Shelby decided to build a carbon-beneficial structure, the use of local timbers for the structure was of utmost importance. Sourced locally from a sawyer who sustainably harvests timber, the structural frame traveled less than 50 miles from source to destination.

The timbers were cut in his brother’s barn over winter, utilizing a handful of carpenters (including Catalyst of HempStone) in a serene and rhythmic cadence of chisel and mallet to wood.

Take a deeper dive into Sustainability in Materials through our blog.

Local Hemp

There are two schools of thought; convince local farmers to grow a new crop and build the processing centers to support it, or find an appropriate use for what is already available as waste.

While we see the need for both avenues,we must respond to what is present. Local hemp is creating tons of biomass that get mulched back into the fields or burned. Both release carbon back into the atmosphere at a rapid pace. This adds to our carbon problem. We must do something to address this.

HempStone works with local, forward-thinking farmers, processors, and regulators to find sustainable solutions to existing waste streams. Shelby Howland was instrumental in helping process local hemp from CBD stalks for testing. These materials are still in development, so are not being used in current construction projects, but we expect that research will prove their viability in the future.

Explore the details of making Local Hemp Processing in words and images!

Local Lime

Lime offers a wide variety of mineral compositions - depending on the geology of where it was mined. Originating from the remains of living things, limestone is a mixture of these remains plus whatever sediment was present at it formed.

Not all limestone is created equal, yet the material is abundant around the globe. In the USA, we are fortunate to have abundant resources of limestone that is appropriate for building.

HempStone prioritizes using the highest quality, most locally available limestone for building and plaster. We are thrilled to have local lime from Lee, MA as one of the main components in our hempcrete mix.

Discover the Critical Importance of Local Lime and the challenges we face when local supply chains cease to exist.