High Performance Tape: Test Results on Hempcrete and Lime Plaster

Over the past several months, HempStone has been evaluating whether high performance tapes could be a viable way to ensure robust air tightness details with Hempcrete.

Boundary Conditions, Qualifiers, and Details

We tested tapes that we had free or easy access to. This included:

Proclima Vana, Profil and Solido Exo (felt finish)

Siga - Fentrim and Fentrim II (felt finish)

3M All Weather (shiny finish)

We were looking for tapes that offered 3 criteria:

Excellent adhesion to hempcrete

vapor permeability

would provide a key for lime plaster

Our tests were relatively short-term, 2-4 weeks, and were conducted in both indoor and outdoor conditions. Tapes were applied to dry and clean hempcrete, and plaster was applied within 3-7 days of tape installation.

Plaster was allowed to cure fully before the plaster demolition was completed on the outdoor test ~ 3 weeks.

The indoor test experienced a catastrophic failure after 10 days of plaster installation.

The 3M tape is vapor closed and was only tested to gauge plaster cohesion for an un-affiliated hempcrete project in Barnard, VT which had already used this tape over window nailing flanges.

We’ve just procured a highly vapor open tape from Rothoblaas, and will be testing this in the coming weeks.

The Purpose of Tape

Tapes provide an effective sealing solution to air and sometimes vapor barrier. They are used at transitions between materials within a single layer of an assembly. For example, tape is used to seal sheets of osb or plywood together at their butt joints when this sheetgood is used as an air barrier.

Tapes in Natural Buildings

Natural buildings are by design vapor open, meaning they allow VAPOR to transfer throughout the assembly. This means that ALL of the materials and products throughout the assembly need to be vapor open. If they are not, then moisture will collect on either the inside or outside face of that material, depending on the prevailing moisture drive at the time moisture is present.

Moisture Drive

This topic goes well beyond the confines of this blog, but if you want to better understand what is happening, I recommend the following articles. Note that a vapor barrier assembly is predominantly used in the building industry, and in some jurisdictions is mandated by code, so much so that it’s assumed that you’ll be building with one. Thus, articles tend to discuss how to limit the perils of this assembly model, rather than focusing on a different (and better) way.

The Difference Between Vapor and Air Barriers by Ecohome

Joe Lstiburek of Building Science Corp explains Thermodynamics: It's not Rocket Science

Quick Building Science Recap:

Vapor is carried in air molecules, and move through an assembly whenever there is a channel for air to pass . So, an airtight building is an essential element in limiting vapor infiltration. Tapes are one product that is frequently used to control airflow at critical junctures of materials along a single plane within the building assembly. The question stands: Are tapes practical on a hempcrete building?

Understanding Hempcrete Assemblies

A note on achieving air tightness:

It’s important to remember that in order to be viable for a hempcrete assembly, a tape MUST meet two criteria - adhesion to the hempcrete, and vapor transmission.

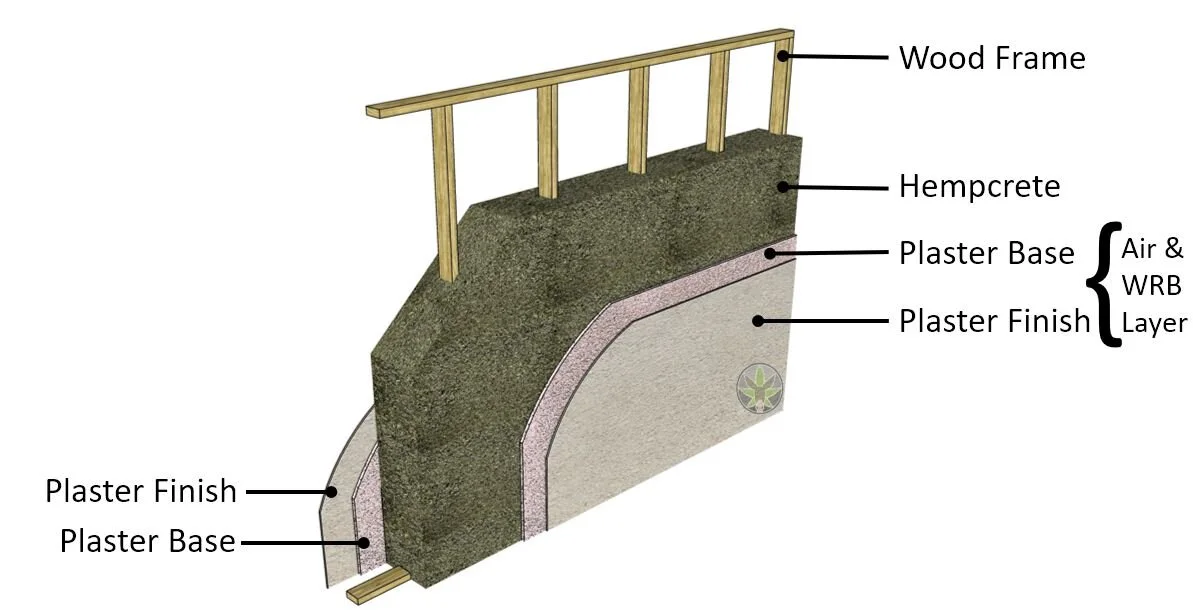

In a hempcrete wall assembly, the hempcrete spans most of the width of the assembly.. If the assembly is finished with lime or clay plastered with either lime or clay, the plaster functions as both the air barrier and the external bulk water layer on the outer face of the assembly.

Therefore, on a plastered hempcrete assembly, a tape must also meed a third criteria - it must serve as a plaster key. Physical connectivity is essential for plaster.

Plaster is a durable and heavy material, that adheres to the hempcrete substrate and functions as a continuous air barrier. Tapes - only found at breaks in the wall, at doors, windows, service voids, and the upper and lower limits of the assembly where foundations and roofing structures abut - serving as a critical connector between the mass wall that is hempcrete, and the windows, door frames, foundations, and roof boards that abut them. If tape is to be used in these locations, the tape must adhere solidly to these disparate materials and also serve as a keyed substrate for the plaster.

In this simple hempcrete assembly, the air barrier is clay or lime plaster.

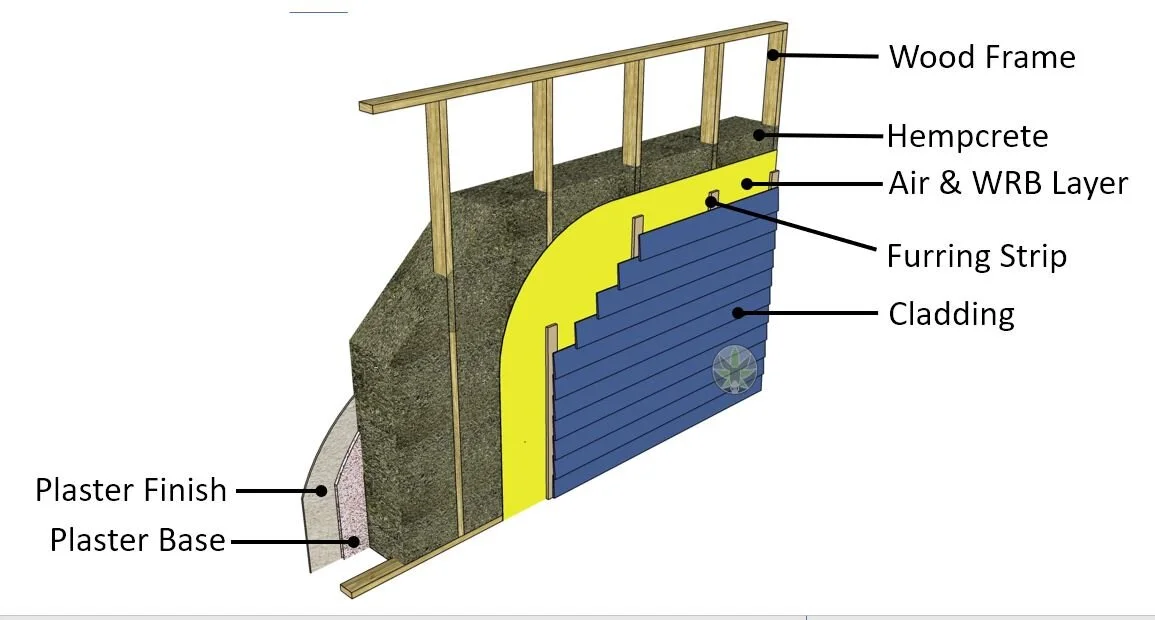

In a wood sided assembly, the air barrier is hidden behind the wood siding, either as a lime or clay plaster, or as a manufactured vapor-open air barrier membrane. This layer is depicted below in yellow. If using a membrane, the air barrier is attached on the face of the hempcrete with the aid of furring strips, and the membrane is lapped and taped at seams. The membrane is also taped to door and window frames, service voids, and the upper and lower limits of the assembly where foundations and roofing structures abut

In this sided assembly, the air barrier can be either lime or clay plaster, or a vapor open membrane

Results

Adhesion to Hempcrete:

Both Siga and Proclima recommended that we use their primer in conjunction with the tapes, as hempcrete performance was unknown. Given the possible vapor permeability concerns, we forgo the primer and chose to test the tape adhesion directly to hempcrete.

All tapes stuck well to hempcrete.

In plaster demolition tests, there was a dramatic decrease in tape adhesion by Siga, and a noticeable decrease in tape adhesion by Proclima.

Although tests were short-term and are thus inconclusive, the significant decrease in tape adhesion caused concern about tape adhesion over time.

Vapor Transmission:

Plaster was demolished and tape removed in order to test the hempcrete beneath.

Vertical edges showed some minor increased in elevation, but were within acceptable moisture levels.

Horizontal edges (where the tape connected the seam between the hempcrete and a wooden base) the hempcrete had moisture levels that were dramatically heightened (well beyond the limits of our equipment), and showed signs of extended elevated moisture conditions. This was evidenced by darkened coloration on the hempcrete behind the entire span of taped area in this location.

Plaster Key:

Felt tapes accepted plaster well, shiny tapes did not.

In demolition tests, plaster broke away from the plaster in sheets, indicating that there was no true key to the tape.

Plaster needs to key to it’s substrate in order to stay integral as an assembly over time. Felt and Shiny tapes do not serve this function.

Conclusion:

The tapes showed a decrease in adhesion over time, an increase in moisture retention behind them, and didn’t serve as a robust plaster key. At HempStone, we are skeptical about the use of tapes as a air barrier support material in a hempcrete assembly when used with plaster. We will continue testing, collaborating with other natural builders who have tried these materials, and engage tape manufacturers about best practices with tape in vapor-open, natural assemblies.

Vapor open tapes could serve a function in a hempcrete assembly that uses a membrane in tandem with a wood siding assembly, so long as the tapes are only connected to wood, aluminum, and other materials other than hempcrete.

You can reach out to Catalyst with any questions: jennifer@hempstone.net