Local Hemp Processing

As a nascent industry, hempcrete is still building a supply chain. US builders naturally want to use US-grown hemp. There’s just a little hiccup - the supply chains are still being developed and refined.

There are several challenges at play, but the most pressing and dramatic need is processing the plant into a viable building material. While this is basically a simple mechanical process, its complicated by the resilience and durability of hemp fiber and stalks. It takes a mighty machine to process the hemp plant as it needs to separate extremely tough and long fibers from the strong woody core. This process is called decordication, and North America is a relative newcomer in decordication development. Demand far exceeds supply.

The second big issue is plant product. Not all hemp is the same - there’s tall, thin, straight industrial hemp grown mainly for fiber (and to build buildings out of) while CBD and THC hemp aims for a shorter, bushier form that encourages flower development. In New England, we had a banner year for bushy hemp, and almost no industrial hemp. Without a significant crop of industrial hemp, we don’t have the option of using local hemp.

Or do we? There are two schools of thought; convince local farmers to grow a new crop and build the processing centers to support it, or find an appropriate use for what is already available as waste. Let’s consider both; build the supply chain we need, and explore the possibilities of what is available now. If we use the Local CBD hemp that is being grown, we can put the carbon that the plant takes from the sky and store it into buildings.

This is a carbon-beneficial alternative to being mulched back into the fields or burned. Both release carbon back into the atmosphere at a rapid pace, which adds to our carbon problem. Using local more effectively is better for the planet in more ways than one.

But how to put this bushy material to use? Decordication machines are designed to process long straight material. In order to process bushes, we need different processing equipment.

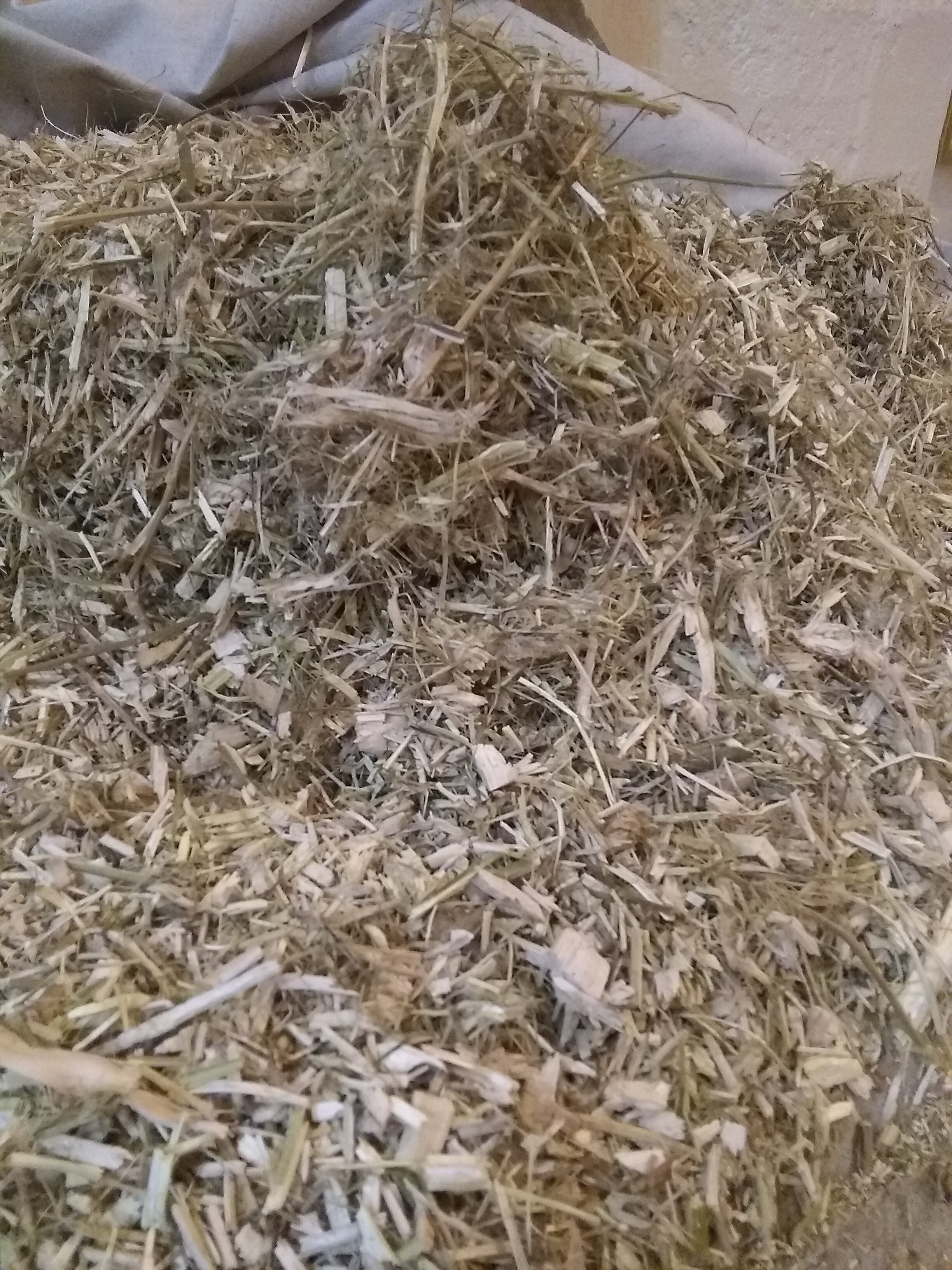

While we don’t attest to know what works best at scale, we had good luck processing a truck-bed of fresh (green) bushy hemp with a Vermeer 6” chipper shredder. The machine produced up to 1.5” chips and a veritable avalanche of long stringy fibers. The material needed a significant amount of hand-processing to get it sorted into usable material; nearly 10 hours in total for what amounted to a few bags of hemp hurd. A slog, but not unbearable for testing purposes.

Throughout inspection and testing, we were quite impressed with the quality of the material. We’ll be testing this hurd in the coming months to see how it compares with industrial hemp as a building material. We’ll keep you posted as we learn more.

Above is our process, in pictures, of converting waste product into viable hemp hurd for construction purposes. This hurd, now formed in 9” test cubes, will undergo thorough testing in 2020 before it’s used in construction.