FAQ - Hempcrete Explained

What is hempcrete?

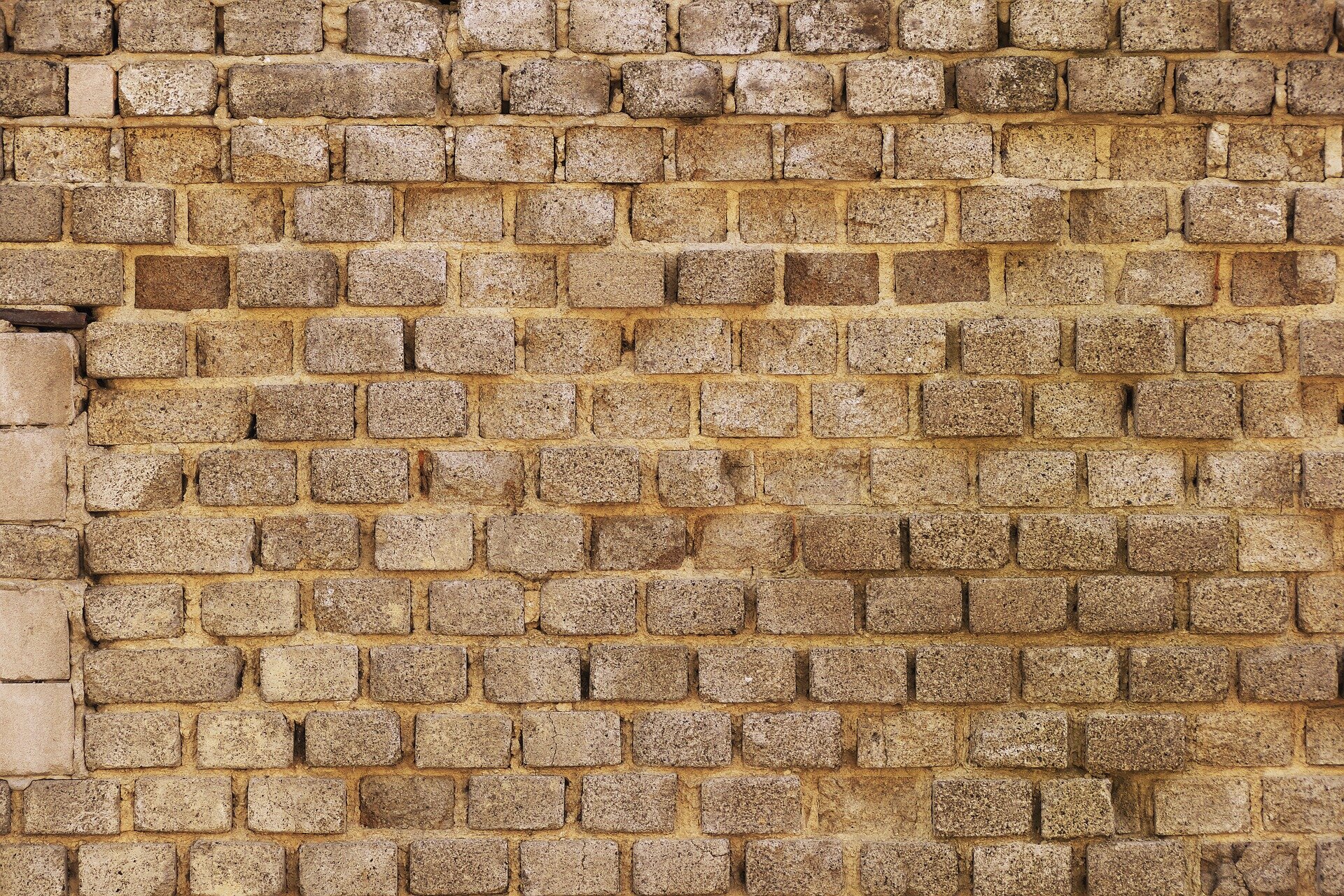

Hempcrete is naturally healthy, resilient, and carbon-beneficial. Made of industrial hemp, a rapidly-renewable plant, and combined with a lime-based binder, hempcrete is a bio-composite insulation and walling material used optimally throughout the building envelope above ground level. Hempcrete's vapor active properties stabilize temperature and humidity to provide a comfortable indoor environment year-round.

Photo Credit: Alex Sparrow of UK Hempcrete

Hempcrete AKA hemp-lime

How is hempcrete made?

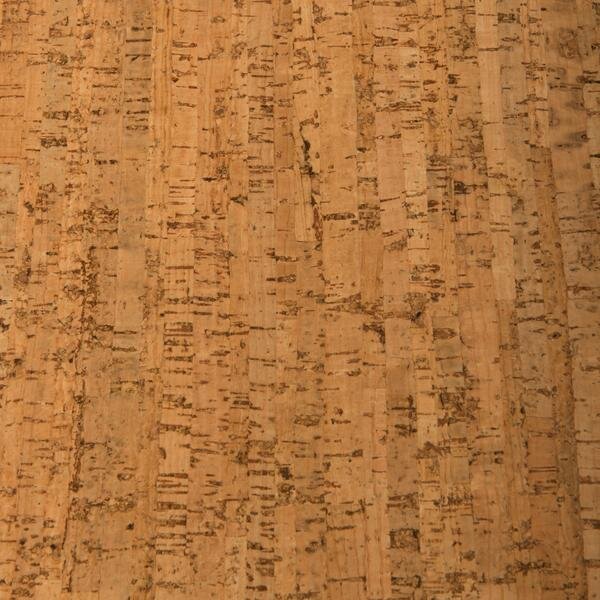

Hemp hurds - small pieces of the industrial hemp stalk - are mixed with a lime-based binder and water is added. The lime binder must be hydraulic - meaning that it sets with the addition of water, and begins to harden immediately. In this process, water acts as the catalyst to create a long-lasting, naturally non-toxic material.

Hempcrete serves as both the insulation and the mass wall simultaneously, and framing is embedded within the hempcrete to provide structure. In floors and roofs, hempcrete is used as an insulating layer in conjunction with other materials.

Hempcrete can be installed 4 ways:

In-situ; placed between removable forms or between wooden joists

Spray-applied against permanent form-work

Stacked in blocks with mortar

Assembled into panels and connected on-site

Where is hempcrete used in a building?

Hempcrete is versatile and can applied anywhere above grade, and is used throughout the perimeter of the building, in walls, ceilings, and floors.

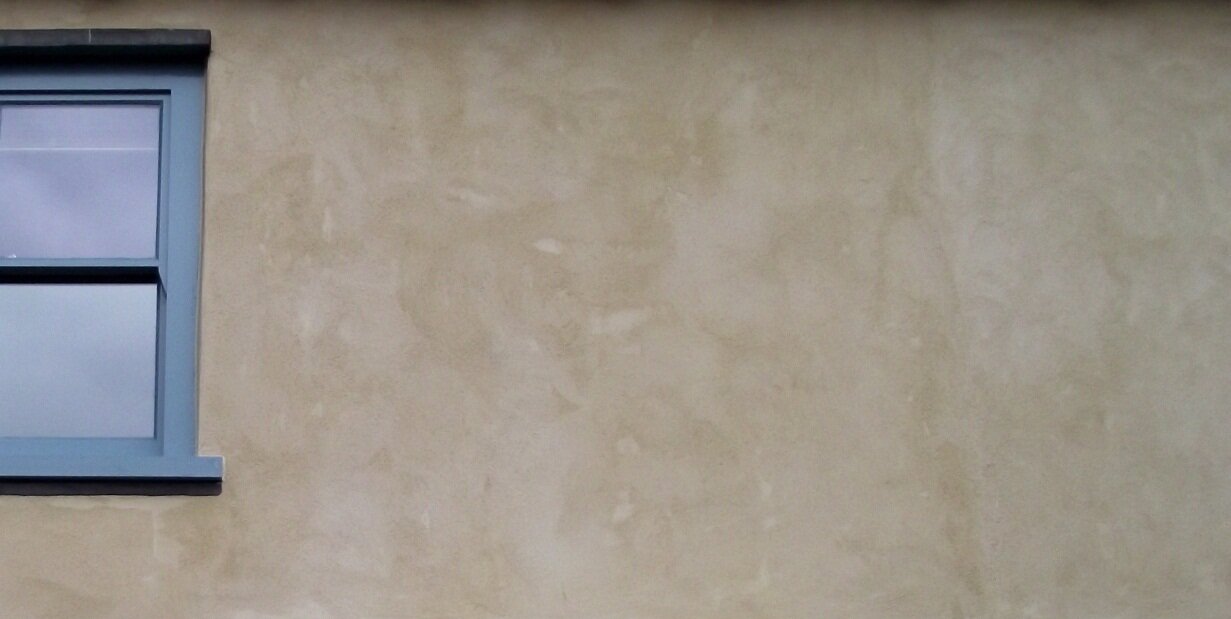

In walls, hempcrete is cast around framing to serve as both the insulation and the mass of the wall. The most simple hempcrete wall can be plastered on the inside and outside for a full wall assembly.

In floors and ceilings, hempcrete is used in conjunction with other materials to provide an insulating layer.

Where in the world is hempcrete?

Hempcrete is used throughout the world in residential, commercial, institutional, and industrial buildings. Developed in the 1980s as a way to repair historic structures damaged by portland cement, hempcrete has developed into a construction industry in both new builds and existing buildings. Hempcrete is popular in regions where hemp is legal to grow and thrives, including Europe, Australia, and Canada. With the passage of the 2018 US Farm Bill, hemp is beginning to be grown abundantly, and hempcrete has become more appealing in the US as well. The US still has a way to go before we can say we have a hempcrete industry, but infrastructure is rapidly being established for this versatile material.

How is Hempcrete Finished?

The most simple hempcrete finish is a natural clay or lime plaster, simply troweled onto the hempcrete surface. However, any natural, vapor-open material can be used with hempcrete: wood, stone, brick, wood wool board. Hempcrete can also be left unfinished on wall interiors for a pleasing aesthetic effect and acoustic benefit.

Why build with Hempcrete?

Good for you, good for the home, good for the environment!

Healthy – Hempcrete is made of just 3 simple and natural ingredients. These inert materials are not only non toxic but help to maintain a healthy indoor environment. Hempcrete can repel fungus, resist mold, deter vermin and insects, and is natural, safe and non-toxic.

Fire Resistance – Hempcrete will not ignite, smoke or burn. In Europe most testing has resulted in 75 minute ratings. In the US and Canada early testing has resulted in 0 flame spread and 0 smoke development. The only other insulating material that comes close is mineral wool.

Insect and Vermin Resistant – Pests do not like lime. The lime alkalinity in combination with the dense and tough nature of hempcrete and its ability to dry out easily does not allow for a hospitable environment for pests. Pests do not want to inhabit or pass through the material.

Mold Resistance - Lime is naturally anit-microbial and anti-fungal. Mold prefers a range between 3-7 PH and because Lime is alkaline at around 12ph, mold will not grow within the structure. Hemp hurd is high in silica and when mixed with lime there is a gradual mineralization of the hurd. Lime inhibits mold growth even with deep saturation of the material.

Thermal Regulating – Hempcrete makes for a very comfortable indoor environment. While lower in static R-value per inch compared to other insulation materials, hemp is not just an insulating material, its also has thermal mass. This means that hemplime can store heat and release it over time acting as a thermal buffer against external temperature swings. Hempcrete installed in thicknesses necessary to achieve adequate “Static” R-value performance standards significantly outperform other insulation materials which don’t have thermal storage capability. Due to this thermal mass, hempcrete has a dynamic or real world R-value well in excess comparably insulated buildings.

Moisture Regulating – Hempcrete can help stabilize moisture levels in a building. The vapor permeability of hempcrete is one of it’s greatest strengths. The ability of a material, assembly or building to absorb and release moisture is its hygrothermal capacity. In addition, hemplime has a high storage capacity both within the hemplime matrix as well as within the porous hemp hurd. This allows even large amounts of moisture to enter but also to then exit the walls as needed - preventing a buildup of trapped moisture within the walls. The hemp and lime work together to regulate the moisture within the building. Lime absorbs, stores, and releases moisture naturally. Hemp stalks are similar in composition to softwood, and resist decay for long periods of time when exposed to water vapor, and can even handle periodic episodes of water saturation without ill effect.

Sound Regulating - Hemplime is an excellent sound attenuator. Hemplime absorbs sound, creating peaceful and quiet spaces that are pleasing to the soul.

Odor Regulating – Sure why not.

Renewable & Biodegradable – Hemp can be grown in 3 months and is compostable. In some climates, two or three hemp crops can be grown each year. At the end of it’s useful life, hempcrete can be mixed into the soil as a biologic and mineral amendment.

Carbon Storing / Sequestering - Hemp is a very efficient at converting carbon dioxide into biomass throughout the stalk of the 10-15 foot plant. This carbon-based biomass, when mixed with lime and used as a walling and insulation material, stores carbon safely in a building envelope for the life of the structure. Lime used in hempcrete is carbon-intensive to extract and process, BUT the carbon stored in the hemp hurd more than makes up the carbon cost planting , extraction, processing and transport of both the hemp and the lime.