The Carbon Footprint Stack Effect of Natural Building Materials

At the Howland House in Goshen, MA, we employed a palette of natural materials in order to compound the benefits of their performance characteristics both in terms of symbiotic design and ecological benefit. We prioritized a judicious selection of local plants and minerals that met 3 criteria: accessible, equitable, and sustainably harvested.

As a result, this home is structurally a timber frame, with local sustainably harvested lumber. Interior wall board, wood trim, and flooring are made of site-based lumber. Local lime is used in plaster throughout the inside of the home and local limestone and “down-the-lane” Goshen stone will be used in finish plaster and Tadelakt.

Local natural building materials, used throughout this building in frame and finish, result in a beautiful, affordable, and healthy carbon-beneficial structure.

The effect is clear: The house is beautiful, and as we illustrate below, our material choices had a big impact on the ecological bottom line. This building is Less-than-Zero Carbon Emissions.

And every home you build can do it too. Chris Magwood proved this in his research on the carbon footprint of building materials where he showed how off-the-shelf materials, when used thoughtfully, can work together to create a zero-emissions building. That was a lightbulb moment for our industry!

Anyone can do this!

Natural Building Materials, used in a complementary manner, serve as a stack effect to flip the negative carbon impact of buildings. Doing so, natural building materials shift the fundamental paradigms of the built environment to be resilient, respectful, and regenerative.

The Builders for Climate Action (BfCA) Carbon Calculator (Beta Test Version 8) served as an easy to use, easy to understand, highly functional tool to assess our material selection performance in terms of CO2 emissions, and informed our choices in the design process.

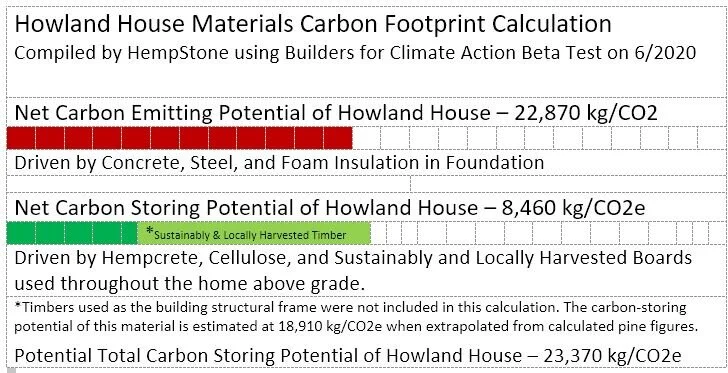

The field of Carbon Footprint Calculations is a nascent industry, especially so for more natural building materials. Chris Magwood’s Builder for Climate Action Calculator is designed to support the frontier of natural building adoption. We tested the use of their program to identity the carbon impact of our materials choices at the Howland Hemp House in Goshen, MA.

The calculator did not create a complete picture - certain key elements were missing:

Local and Sustainably harvested timber frame

European high performance tape and membranes

Services information

Where this program excelled was the database of natural building materials. We found data on to directly or indirectly assess the carbon impact of a structure that prioritized local, sustainably harvested materials. The program is easy to use and lays elements of the buildings in terms of assemblies, so that you can see the ecological impact at each material and component.

The Foundation is dominated with materials that are high in embodied carbon. While this is typical for foundations, the Superior Wall system added the impact of both XPS and EPS, two rigid foam materials that are at the top of the list of embodied carbon, as well as steel framing, which is also a high-embodied carbon material. Only cellulose makes it into the positive as net carbon-storing material for this graph.

Carbon Footprint by Assembly with material calculations

Foundation Materials can be VERY Carbon Intensive! The forefront of emissions reduction strategies are Below Grade, and several good options exist. However, these materials and practices are not yet embedded in the industries building practice. To learn more about Carbon Conscious Foundations, check out our post.

Where the program really made a difference for us was in the material choices above grade. Shelby made a single choice to switch from drywall to locally sourced, sustainably harvested pine boards, and flipped the coin on the carbon impact of that wall assembly. If we’d had the tool earlier in the design process, we could have had the opportunity to make that kind of impact in the foundation as well. As you see, the materials choices below grade have the most room for improvement.

You’ll see a LOT more green as we move above grade. In fact, so much so that the carbon emitting materials start to stand out.

You may be surprised to see wood - a plant, over on the emitter side of the graph. Stud framing, plywood, and OBS - all made of wood - count as a net carbon emitter, while local and sustainably harvested lumber is a net carbon storing material. This is due to the difference planting and harvesting practices, manufacturing processes, and transportation.

Carbon Footprint by Assembly/Unit with material calculations

The fact is that this project has gone way beyond the norm in terms of finding local materials. We have a rich forest and abundant mineral deposits here in New England. We are able to capitalize on local, sustainably harvested materials. Yet most of that carbon benefit has gotten chewed up in the carbon emissions equation of the foundation. Shelby chose a Superior Wall system in order to lower the ecological impact of the concrete of a typical foundation and footer. However, the ecological impact of the XPS, EPS, and steel framing more than made up for the carbon equivalent, and made for overall a higher embodied carbon foundation. ….Que Game Over music from the 80’s.

Fortunately for us, Builders for Climate Action came to the rescue. We were able to quickly put in area and volume figures of our building, select from an option of common building materials and carbon-conscious options. The carbon impact of each selection was on the screen - we could literally see the impact that a change from drywall to pine boards would have. And in doing so, we were able to negate the effects of this high-embodied carbon foundation, and come away with a less-than-zero carbon emissions building.